When estimating the total capital cost for your facility, it’s important to go beyond the equipment sticker price to determine the full, or complete, cost of the system you’re installing. This is exactly what upper management expects when they request a scope for new equipment. This is considered to be Preliminary Engineering. You want enough detail to accurately estimate costs without developing the fully detailed engineering packages for construction.

So, what should be involved in your full scope? Here are 6 engineering costs that project engineers often overlook during the scoping phase. This approach allows for an accurate cost at an economical price.

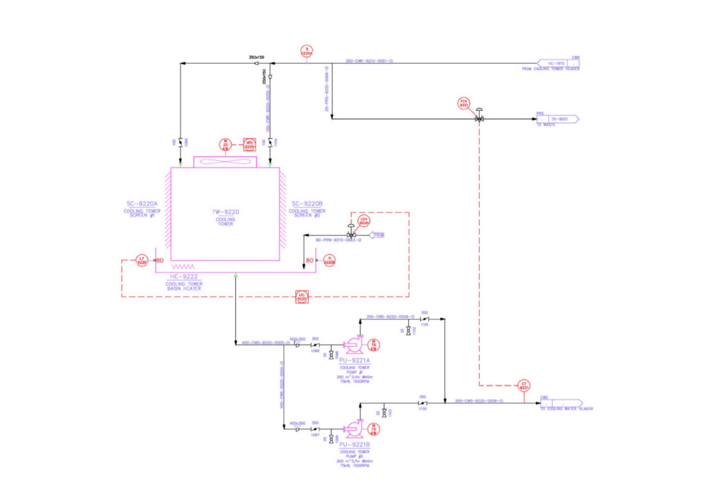

Process & Instrumentation Diagram (P&IDs)

Beyond the major equipment and location of the system, how can you determine the ancillary requirements for your equipment to become operational?

These decisions are made within the Process and Instrumentation Diagrams (P&IDs). These critical documents will outline the pumps, instruments, utilities, piping, and other special parts required to operate your equipment. Having complete and thorough P&IDs will help you properly identify those components, too.

Mechanical Layout Preparation

Once you have determined the equipment sizing, an engineer can help you determine the general arrangement of the entire system. This is a concept mechanical layout of your system that starts putting some details around the process.

Here are some Important items to consider in the Mechanical Layout phase:

- Size of the equipment bays for steel framing.

- What are the floor elevations going to be?

- Do you have enough room to slope spouting for gravity-flow products?

- How is the facility going to be staffed? Do you need a control room, restroom and breakroom?

- Is there enough room for maintenance to access pumps, motors, agitators and other equipment?

- Incoming raw material storage, product tank storage, chemical storage?

- Do you have enough storage for the plant to operate through the holidays and bad weather?

- Road access and truck traffic patterns into and out of the facility.

- Is there room in the layout for cable trays and conduit?

- Is there room in the layout for pipe racks?

- Do you need a Motor Control Center and I/O room?

These drawings will be crucial for estimating the total cost of the project—and should consider, heavily, the impact of construction on current plant operations. Once you have a good mechanical layout, you will be able to accurately price structural, electrical and piping.

Site Selection Determination

Before your new capital equipment can be delivered, you’ll need to determine where it will live on site. Where it’s placed can have dramatic implications on the cost of construction, costs of materials, costs required to port utilities, and chemicals. You probably have a good idea of where you want it located. Now that you have the mechanical layout, you can verify that it actually fits.

To get a sense of what you’ll have to spend on site prep, ask yourself questions like these:

- What is the weight of the new equipment full of product?

- What are the seismic and wind load requirements for the site?

- What are the structural steel and foundation requirements?

- Is the site prepped to run utilities and raw materials for construction and operation? Are pipe bridges required?

- What are the environmental and conditions of the site?

- What underground utilities are in the area? What are required?

- What is the water table elevation?

There are almost always surprises lurking below the surface. For new installations, a geotechnical report will be required to determine the load bearing capacity of the soils. A structural engineer can then assemble a structural concept and estimated cost. Brownfield sites usually require a significant amount of demolition and excavation work.

When installing equipment in an existing building, it cannot be assumed that the existing concrete or structural steel will be adequate for support. It is common to excavate and pour a new slab at ground level or add support steel under elevated concrete floors for new equipment loads.

Planning for them, and the engineering and construction costs that come with them, will ensure you have a more realistic budget.

Electrical System Evaluation

Another important cost driver surrounds the way you’ll power the system.

Early on, you’ll need to confirm the current electrical or power system has the necessary capacity to power your equipment and process. You may also need to specify and scope components or materials to run utility to your equipment or operate your equipment. This includes things like cabling, motor starters, etc.

You’ll also need to determine the electrical needs for the site itself—such as exterior or interior lighting. An electrical engineer can help you plan accordingly for your system.

Here are some critical questions that need to be answered:

- What is the total connected motor load?

- Where is the closest substation and what is the current loading?

- Do you need a transformer?

- Can you run wire from an existing MCC or do you require a new MCC (Motor Control Center)?

- What is the length of wire pull from the MCC to the equipment?

- Is the area classified for combustible dust or solvent vapors?

- Are you going to use cable tray or conduit?

- Is there a corrosive atmosphere where specialty materials of construction are required?

- What are the lighting requirements?

- Are you going to include power factor correction?

Piping Design and Other Utilities

A critical component to the operation of your system is the piping that will safely transport fluids or gas in and out of the process equipment. Depending on the stage of estimating, This work can be extremely complex. A piping engineer can work with your team to determine pipe line sizing, piping materials, and pipe routing design.

With a good P&ID and Mechanical Layout, piping lengths can be estimated. There are unit costs available per inch-foot of piping (inch diameter x length). These factors will vary based on materials of construction. Polished stainless tubing will be different from mill finish stainless pipe, schedule 80 carbon steel pipe or copper tubing.

There are several key factors to consider in estimating the true piping cost:

- Materials of construction

- Are there any special alloys, such as 2205 duplex stainless or alloy 20?

- What is the pipe routing going to be?

- Did you leave space in the mechanical layout for pipe racks and chases?

- What utilities are required: Natural gas, steam, condensate, tower water, chilled water, caustic, acid?

- Where are the closest utility tie-points? Do you need additional racking to the new installation?

- Are the utility headers large enough to accommodate the additional load?

- Did you include an allowance for piping supports?

Piping is a significant cost in many systems. This approach will ensure that you have an accurate cost in the preliminary engineering phase without spending a lot of money on detailed engineering efforts.

Control System Evaluation

A good P&ID will give you an accurate instrument list and I/O count. It is always a good idea to discuss the controls with operations. They will have insight on effective controls strategies and instrumentation needs. There are other a number of considerations that affect the price of controls. These include:

- Are you going to standardize on what the plant already has in place or is this the time for an upgrade?

- Are you going to go with a true Distributive Controls System (DCS) or a PLC based system?

- What does your network architecture look like? Is it going to be conventional or Foundation Fieldbus, Asi-net, Device Net, Profi-bus or Ethernet?

- Are instruments going to use SMART transmitters? Are they HART compatible?

- Do your instruments need to be intrinsically safe for classified areas for combustible dust or solvent vapors?

- Did you include programming?

- Is all the communication cabling coming back to the control room or are you using remote work stations?

The controls platform you choose has a significant impact on cost. Even within DCS systems, the price can vary significantly depending on data logging capability and other features. The communications protocol will affect cable material costs. Area classification will significantly increase the cost of instruments. These are all things to consider when estimating the real cost of controls.

Bringing It All Together

When tasked with scoping new capital equipment for their facility, project engineers frequently focus on the sticker price rather than the true price of the system.

There are different approaches that can be taken.

The first approach would be a factored estimate. This is where the total price is factored from the equipment price and gives you a +/- 50% cost. This exercise is used to determine a rough return on investment. It helps to determine if you should spend any more effort in moving forward with refining the project scope.

The next level of detail would be a +/-30% estimate. This requires a preliminary P&ID that may not have all the details yet, as well as a preliminary mechanical layout. In this case, the site may not be selected yet, however structural costs can be estimated based on a region or state. There is typically not a lot of detail around instrumentation and controls, so these disciplines are factored off the total price.

The approach outlined above will yield a +/-20% to +/-10% cost estimate, depending on how complete the information is.

Each of the engineering requirements outlined above come with their own costs—both for the services of the engineers, and for the additional components and materials outlined in engineering specifications. Neglecting these costs early will set improper expectations with upper management and can also have significant impact on the project schedule.

The trick is to find out what else you need before you submit your proposal for approval. That will help the business plan appropriately for the new system. This is a good time to get an engineer involved. AMG has the resources and knowledge to help you develop the critical details that impact the cost of your project. We take actual project costs and use those to develop unit installed costs for concrete, structural steel, piping, electrical and instrumentation. All these activities take time that you may not have. AMG can help you fill in the gaps to provide a timely cost estimate.

Currently in the process of scoping new facility equipment? Reference our Project Engineer’s Guide to Facility Systems and Installation to make sure you’re considering the full scope of activity.