Have you been tasked with scoping and pricing a new cooling tower? If it’s your first time taking on a big task like this, it can be intimidating. Mistakes on projects like these can be easy to make and result in significant unplanned costs.

When faced with those realities, a lot of project engineers simply let their vendor or contractor size and scope the tower without getting too involved in the design and decisions. That’s where trouble can start because systems like these are unique, just like the jobs they’re designed to do. One size does not fit all. What works for one process on a summer day in Minnesota may not work for another on the hottest day in Nebraska.

That’s why starting with a good base of knowledge is critical. And why we’ve put together this quick nut-and-bolts cooling tower primer.

The Purpose Of A Cooling Tower

Almost every processing facility needs cooling. If steam is coming in, or doing any kind of heating, you have to take the BTUs out at some point. A cooling tower is, in essence, a heat exchanger. It rejects waste heat to the atmosphere by using air and water in direct or indirect contact to remove process heat and bring a water stream down to a lower temperature.

Wet Type vs Dry Type vs Hybrid Cooling Towers

There are a variety of cooling towers types, and they can vary in size from small roof-top units to large stand-alone hyperboloid structures that can be hundreds of feet tall. They’re named for the cooling method they employ: wet type, dry type and hybrid type.

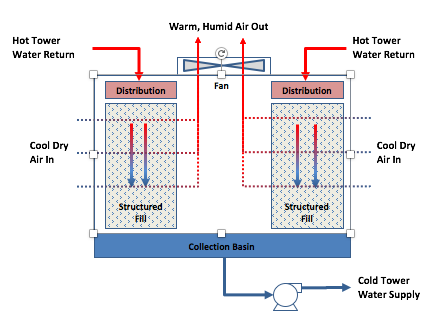

- Wet type cooling towers are the most common. As the names suggest, they allow a small portion of the water being cooled to evaporate into a moving air stream to provide significant cooling to the rest of that water stream. For obvious reasons, these are known as “evaporative” systems, and the heat from the water stream transferred to the air stream is then discharged to the atmosphere. Because the cooling potential of a wet surface is much better than a dry one, wet type systems are commonly used for processes that require significantly lower water temperatures.

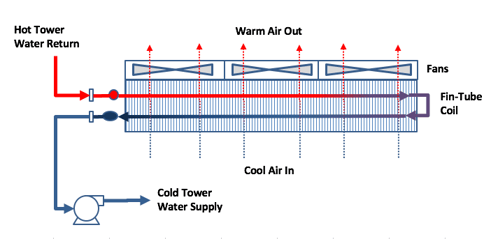

- Dry type cooling towers are what are known as indirect contact towers. In them the water is pumped through plates a heat exchanger coil and cooled with air. You don’t get the evaporative cooling affect a wet type tower provides, but if you don’t need to get the water temperature down below, say, 100 degrees Fahrenheit, a dry type tower can be very effective, and more energy efficient in very humid environments. A good example of a dry type cooling system is the radiator in your vehicle.

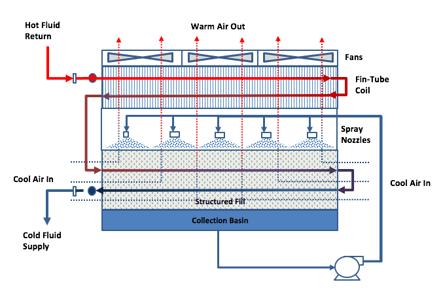

- A hybrid type system uses a combination of direct and indirect cooling for heat rejection. In some cases, it can be a combination of an indirect cooling exchanger with outside water spray. In others it can be a wet type tower used to cool the refrigerant loop for a large chiller systems. In either case, it combines the methodologies of both wet and dry types to achieve the required cooling. Applications include heavily urbanized areas where the vapor plume is undesirable or arid environments where only a small amount of evaporative cooling is needed to reach the cold water temperature.

Speaking of chillers, they’re an alternative or complementary cooling option. They use a refrigerant fluid to supplement cooling, and they may be the right application for some processes and locations. They’re more expensive to operate, but for companies with unique or seasonal needs (in the summer, for example, when you have higher humidity and need a supplemental system to get water temperatures down an extra five degrees), they can make a sensible option.

Choosing the right cooling tower type for your operation really depends on what you’re trying to cool and the temperature you need to get it down to. The best advice is to know your product and your process, and choose the option that gives you the most precise, efficient, cost-effective cooling.

Cooling Tower Design: The Biggest Decisions

Now that we’ve covered the different types of cooling towers, let’s dig into some of the things you’ll want to think about when designing yours. And size and location are the key factors.

Tower Location: You need to decide where it’s going to sit. Rooftops are an option if you’re pressed for space, but some towers can be pretty sizable and need to stand on their own. They also need very good airflow, which means putting them next to another building can be problematic. Keeping them free of compromising debris can be tough, too, so placing them near load-outs and emission sources may be a bad choice. There may not be a perfect location, but one that minimizes these issues will be better.

Water Pump Location: This can be a bit of a double-edged sword. It’s best not to locate the tower too close to building, but close enough to put the pumps inside so that it they won’t freeze in the winter. For remote tower locations, a removable, heat-traced box or a small heated building may be necessary.

Pipe Sizing: The location of the water pump partially determines your pipe sizing, which is another important design factor. Locating the pump away from the building demands longer suction piping. But if you size the pipe right (i.e., bigger), you should have no problem going farther away. You also want your pipes big enough to prevent pump cavitation issues. Unfortunately, because manufacturers want to keep their prices competitive, they tend to spec the smallest size pipes they can. So be sure to specify the pipe and nozzle sizes you actually need.

Header Sizing: Another piping-related consideration is the header size for utility piping out to the plant. Going with a bigger bore pipe will generally allow you to have longer runs, keep velocities down and prevent bottlenecks. You may not know those measurements in advance, but a bigger pipe is probably better.

Water Pump Sizing: Sizing the tower water pump can be a challenge, too. Keep in mind that you need the pump to develop enough pressure to get water to the highest and farthest places in the plant. If you don’t size the pressure drop right, it won’t get there. Pumps are typically sized for 65 feet of head. In our experience, though, 90 feet of head is what you really need to make sure your pump can do that job. But you need to know for sure.

Determining the design pump flow is not always straightforward, either. There could be intermittent users, seasonal users, and small users where you don’t know the load, such as hydraulic oil coolers. Plants commonly operate over the design capacity, which means the cooling tower needs to keep up. It is important to have some excess flow in the pump and tower design for these situations.

Basic Cooling Tower Equipment

Determining a cooling tower type and understanding some of the key design considerations will get you headed in the right direction. But they won’t keep your tower up and running. That will depend on reliable components and preventive maintenance.

There are structural components, which include:

- The Cold-Water Basin

- Tower Framework

- Water Distribution System

- Fan Deck

- Fan Cylinders

- Fill

- Drift Eliminators

- Casing

- Louvers

- Access And Safety Components

There are mechanical components, which include:

- Fans

- Drive shafts

- Float Valve

There are electrical components, which include:

- Motors

- Motor controls

- Variable Frequency Drives

- Wiring systems

- Control instruments

- Basin Heater

Each of the items above need to be thoughtfully spec’d and budgeted for—as well as planned for maintenance and repair activities. It is important to understand what a supplier has included in their price and what you will need to furnish in addition.

If you’re designing a complete system, you’ll need plenty of ancillary equipment and components as well. These items may include:

- A supporting structure (i.e., pad, legs)

- Access walkways / ladders

- Piping

- Utilities

- Tower Water Pump

As you can see, a cooling system is more than just a tower. It’s a complex network of parts and systems and processes. Making sure yours does the job you need it to do depends on keeping all those parts in mind at the beginning so they don’t let you down in the end.

Common Cooling Tower Oversights

Even if you design and prepare diligently, issues can arise. Anticipating some of them can allow you to plan better at the outset and make dealing with any that come up a little less stressful.

- Tower Sizing: The biggest challenge deals with sizing. And that’s especially true in areas where the conditions change over the course of the year. If you size your cooling tower for an average condition, it may not get the job done in the peak of summer or the dead of winter. Air temperature and humidity impact wet type towers the most. They need to pull sufficient airflow in any condition, and you need to be sure you have enough surface area to do that. Sizing your tower right for the extremes from the beginning is the best way to avoid this issue.

- Pipe Sizing: We mentioned pipe sizing earlier in the design section, but it bears repeating. When pump suction piping isn’t sized properly (they’re usually too small), you run into issues. Size it right for the process and pump location and you’ll save yourself a potential headache.

- Add-Ons: Expansion can be another pitfall. If you design your cooling tower for a set capacity, then increase the load over time with add-on projects, it’s not going to cool the way it should. If you’re scoping from scratch, consider what other processes may need to feed into the tower in future. Then make some adjustments in the design phase (e.g., motor size, blade pitch) that can increase your cooling capacity without requiring a new tower structure down the line.

- Fouling: When cooling towers suck in air, that’s not the only thing they suck it. Dust, dirt, leaves, seeds and anything else that’s flying by can get sucked in, too. That makes fouling another common problem. Making sure you include a strainer basket in your scope can limit the rather dirty work of cleaning the tower out. And take it from our engineers who’ve seen what can wind up in there, it’s a task you don’t want.

Proper planning early in the scoping phase can help to forecast and prevent many of these issues. Bringing an experienced engineer to the table early is a wise investment.

The Importance of Getting Good Advice

Whether you’re nearing capacity with the cooling system you have or are in the design stage for a new one, think before you buy. Don’t let inexperience or a lack of internal resources lead you into a costly (in more ways than one) mistake. Talk to an engineer. Gather the necessary process information. Make informed decisions. It may just save you (and your project) in the long run.